Boron steel, an alloy of iron and boron, offers superior strength and durability in automotive manufacturing and collision repair. Its extreme hardness requires specialized cutting procedures such as plasma or laser cutting. Drilling into boron steel necessitates high-speed tools with advanced tips, steady feed rates, and cooling lubricants to prevent damage and ensure precision. These tailored methods preserve structural integrity for clean cuts, ideal for luxury vehicle repairs and collision services.

Can you drill into boron steel without sacrificing quality or performance? This guide explores the unique composition and properties of boron steel, a versatile alloy known for its strength and hardness. We delve into effective cutting methods, from traditional techniques to modern approaches, focusing on minimizing damage during drilling. Discover expert tips and best practices for mastering boron steel cutting procedures, ensuring precise and efficient results without compromising material integrity.

- Understanding Boron Steel Composition and Properties

- Common Cutting Methods for Boron Steel

- Effective Drilling Techniques for Boron Steel Without Damage

Understanding Boron Steel Composition and Properties

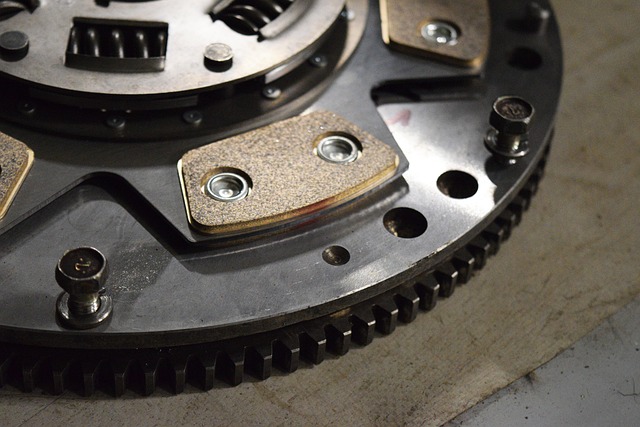

Boron steel, a unique alloy, combines iron with boron to create a highly specialized material. This metal’s composition offers exceptional strength and durability, making it ideal for demanding applications. Boron, as an additive, significantly enhances the hardness and tensile strength of steel, making it resistant to wear and tear. This makes boron steel an attractive choice for various industries, including automotive manufacturing and collision repair services.

The properties of boron steel are particularly advantageous when it comes to cutting procedures. Its hard surface allows for precise and clean cuts without chipping or deforming. In the context of luxury vehicle repair, where meticulous craftsmanship is essential, boron steel’s resistance to damage during cutting processes is invaluable. This feature ensures that even intricate designs and delicate components remain intact, providing superior results in vehicle dent repair compared to conventional steels.

Common Cutting Methods for Boron Steel

When it comes to shaping and cutting boron steel—a high-strength alloy known for its exceptional hardness and durability—the choice of cutting methods is critical. Traditional tools like hammers, chisels, and hand files are not effective due to the material’s extreme hardness. Instead, specialized procedures are employed to ensure clean, precise cuts without compromising the structural integrity of boron steel, especially in applications such as auto body repair at a car body shop or intricate auto repair work.

Common cutting methods for boron steel include plasma cutting and laser cutting. Plasma cutting involves directing a high-velocity jet of ionized gas at the metal, creating a precise cut with minimal heat input. This technique is ideal for thick sheets and complex shapes, often used in industrial settings like car body shops to fabricate and repair auto parts. Laser cutting, on the other hand, employs a concentrated beam of light (laser) to melt or vaporize the metal, offering exceptional accuracy and fine detail. It’s particularly useful for intricate patterns and curves, although it may be more suitable for thinner boron steel applications in an auto repair shop setting.

Effective Drilling Techniques for Boron Steel Without Damage

Drilling into boron steel requires a thoughtful approach to prevent damage and ensure precision. Boron steel is known for its exceptional hardness and strength, making it a popular choice in various industries, from automotive components like bumpers and fenders (collision repair services) to industrial tools. When employing drilling techniques, professionals should adhere to specific procedures tailored for this material.

One effective method involves using high-speed cutting tools with advanced carbide tips designed for boron steel cutting procedures. These tools minimize chipping and delamination by generating less heat during the drilling process. Additionally, maintaining a steady feed rate and applying a cooling lubricant can significantly reduce friction, preventing damage to the drill bit and the steel surface. This meticulous approach ensures that even when drilling through thick boron steel panels (car scratch repair), the integrity of the material is preserved, facilitating clean cuts without compromising the structural integrity of the component.

Drilling into boron steel without compromise is achievable through understanding its unique composition and employing suitable cutting techniques. By adhering to effective procedures, including utilizing specialized tools and precise methods, it’s possible to create clean holes while preserving the superior mechanical properties of boron steel. This article has outlined essential steps for successful drilling, empowering readers with knowledge to navigate the challenges posed by this robust material, ensuring both precision and integrity in their projects.